To enhance competitiveness, KIRIU devises techniques through considerable experience of casting development, process design and KAIZEN, and applies those techniques to produce quality brake discs, and draws on it to new parts production.

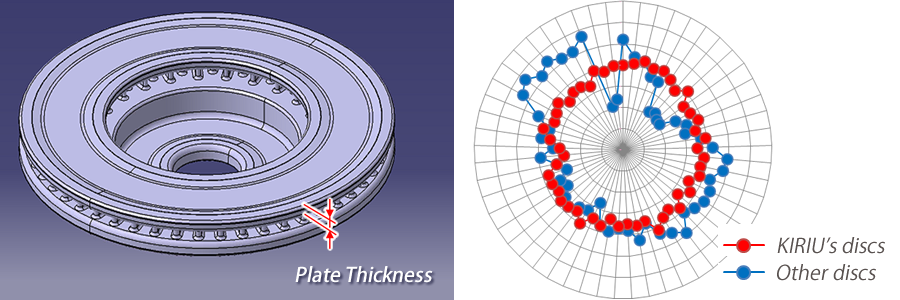

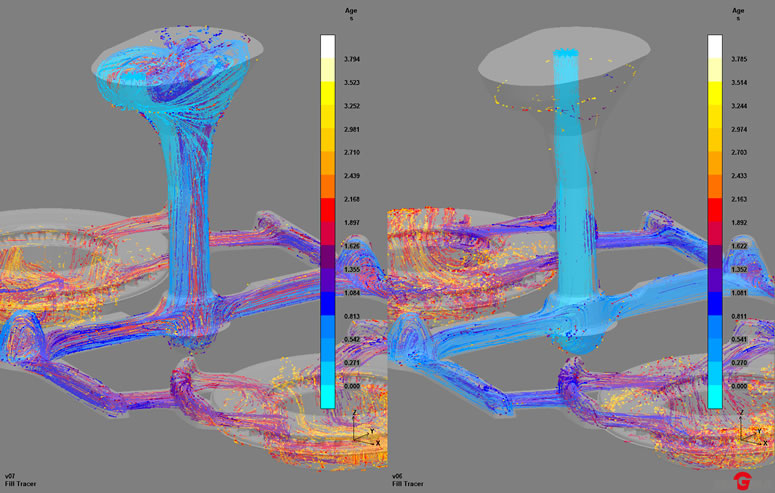

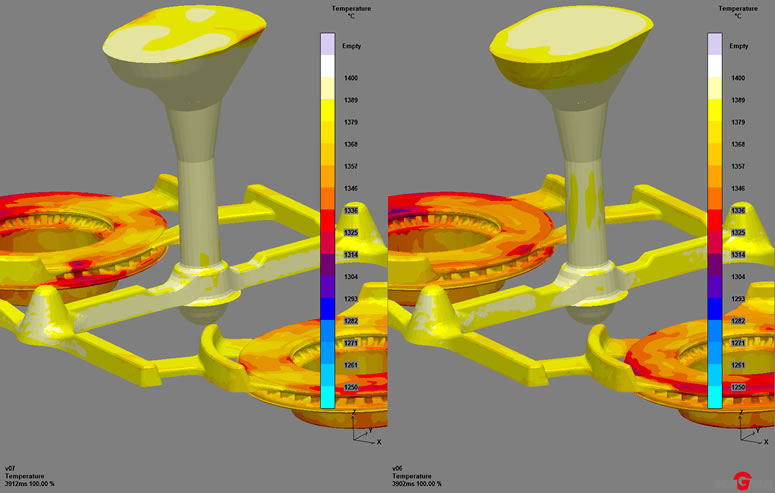

We achieve homogenization of graphite structure, and high accuracy in dimensions through simulation of molten metal malleability and temperature distribution during solidification.

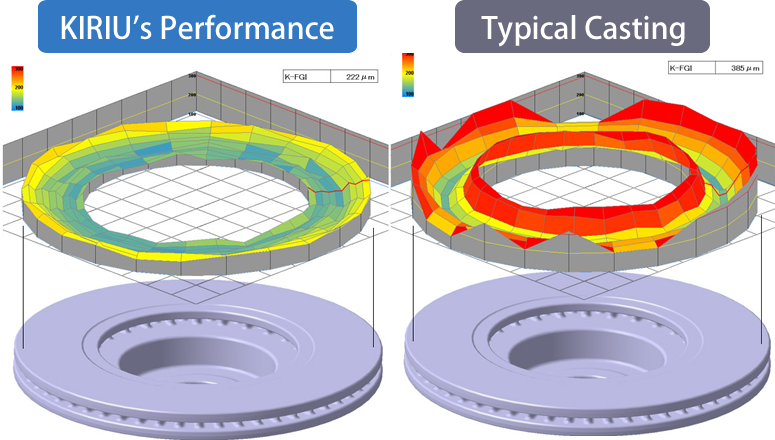

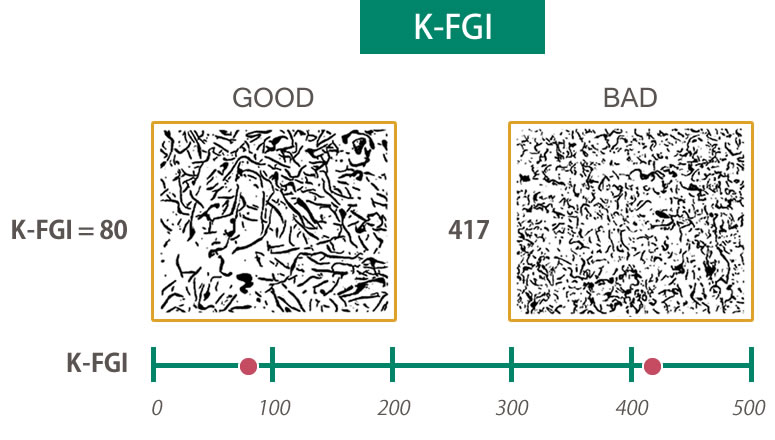

"K-FGI" is our unique method to quantify graphite structure. Using K-FGI, we achieve the consistent quality of a brake disc, while minimizing variation of graphite structure. KIRIU group provides consistent quality products around the world.

K-FGI stands for "KIRIU Flake Graphite Structure Index." It measures the level of graphite structure based on a quantification index.

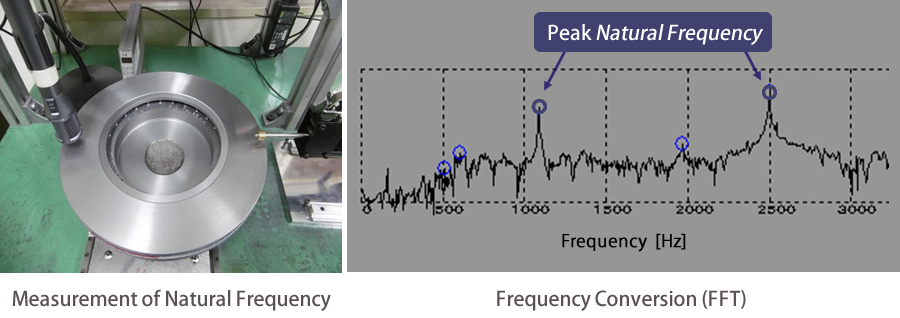

Using our accumulated capabilities, we optimize casting conditions, while minimizing the variation of natural frequency of a brake disc. By controlling the natural frequency, resonance can be minimized, so that brake noise is reduced. Our products can fulfil our customers' performance specifications.

Accurate casting contributes to both weight saving and improving performance.