|

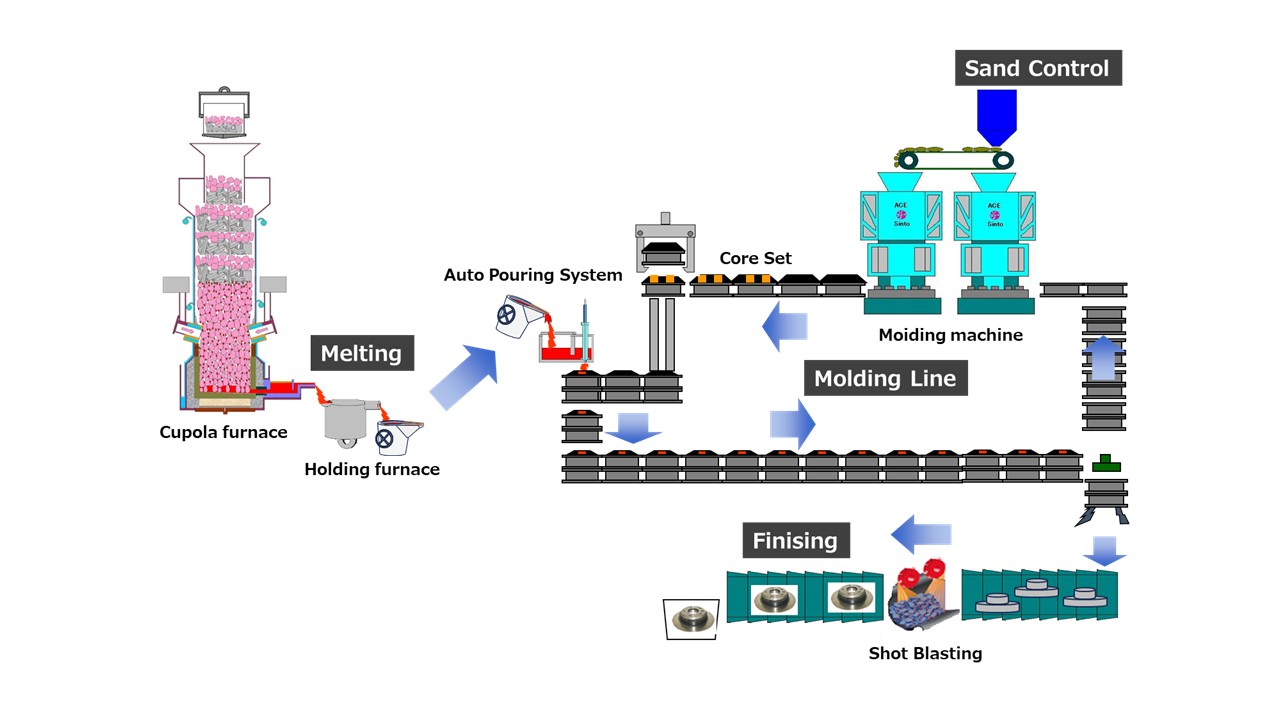

STEP1:Sand Treatment The agitator type mill is used, which enables precise and uniform mixing. |

|---|---|

|

STEP2:Sculpting Employing a static molding machine to produce high-quality molds (uniform and high strength), this line improves efficiency by simultaneous upper and lower molding.The frame size of 900 x 900 allows flexible production of large parts and small parts. (High dimensional accuracy and Weight reduction is possible.) |

|

STEP3:Melt High-temperature hot-air water-cooled cupola in a high-performance heat exchanger is used for long-term continuous melting. |

|

STEP 4: Finishing & Inspection Rough materials undergo thorough inspection by qualified and certified inspectors who have completed specialized training to ensure compliance with quality standards. |

We have established the most advanced production lines in the world with our unique production technology. By fully utilizing the latest equipment such as NC machines and transfer machines, we have established a highly efficient and flexible production system from extremely small lot production to mass production of various products.

We have provided a low-cost product by in-line coating using dielectric heating (Induction Heating) for drying electrostatic powder coating.